- Home

- introduction

-

products

- Pipe Expanding Machine

- Hot Elbow making machine

- induction Pipe bending machine

- Steel pipe internal grinding machine

- Steel pipe external grinding machine

- Hydrostatic pipe testing machine

- steel pipe Flaring machine

- steel square pipe making machine

- steel pipe straightening machine

- steel pipe beveling machine

- Tee Making Machine

- Cold Drawning Machine

- Cold Elbow Machine

- Intermediate frequency power supply

- Graphite sprayer

- Seamless taper pipe machine

- seamless tapered steel pipe

- our customers

- news

- contact us

Induction Elbow Machine

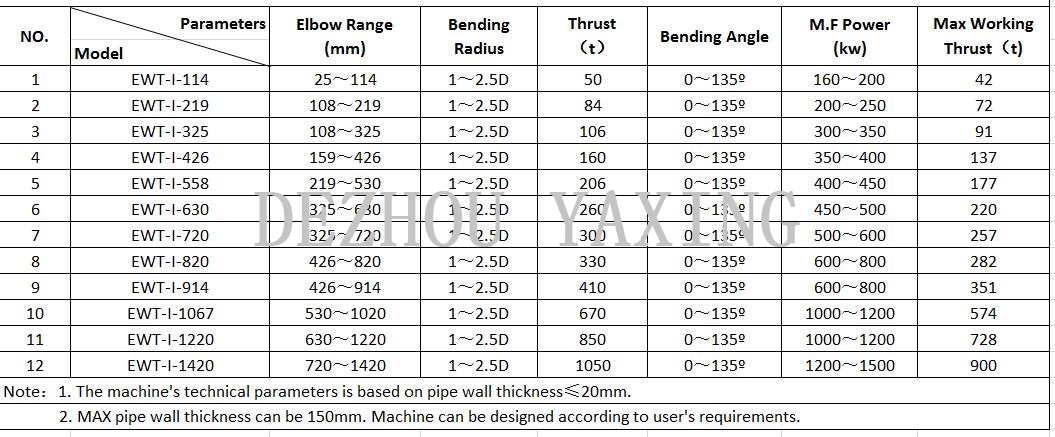

EWT-1 Medium Frequency Induction Heating Hydraulic Elbow Machine

Medium frequency induction hydraulic elbow machine is a traditional product of Dezhou Yaxing Steel Tube Equipment Factory, which is mainly used for producing a variety of elbows in 1D ~ 2.5D. With the development of steel pipe deep processing technology in the factory, this product has gotten a full range of technical improvements. It combines together extra-short stress line taper mold expanding technology, digital control medium frequency induction heating technology, back pressure free, no back pressure low-energy consumption hydraulic transmission technologies. All push plate gates adopt electromagnetic reversing valve, which has realized gate double control at site and operation desk and increased multiple operation automatic technology such as mother pipe hydraulic align and right clamping.

Combined with our factory expanding machine technology, we developed four-cylinder extra large and thick bend pipe fitting pushing machines. One person can control several sets of equipments after it is equipped with medium frequency power supply and smart thermostatic control system with featured of energy saving, environmental protection and safety operation.

1. Elbow technical parameters:

1) Elbow range:OD:φ25mm~φ1420mm;

2) Wall thickness:5mm~120mm;(sectional design and manufacturing the equipment)

3) Angle:22.5°,45°,90°,135° and random angle user demands

4) Elbow bending radius range:1D~2.5D

5) Mother pipe material:seamless steel pipe, straight welded pipe and spiral welded pipe.

6) It can push kinds of bend pipes with different radius as required, also called unequal diameter bend.

2. Structure:equipment base and guide rail, main oil cylinder and support plate, active push plate, front support plate, loading mechanism, medium frequency coil adjustment mechanism ( medium frequency heating coil, elbow die, mould pull rod), medium frequency power supply heating mechanism, electric control system, hydraulic control system, operation desk(touch screen), water cooling circulating system.

3. Auxiliary equipments: hydraulic press(elbow reshaping and mould shaping use), elbow reshaping moulds, elbow mouths reshaping moulds, elbow beveling machine, steel pipe sawing machine, steel pipe inside wall high temperature lubricant (graphite)

spraying equipment.