- Home

- introduction

-

products

- Pipe Expanding Machine

- Hot Elbow making machine

- induction Pipe bending machine

- Steel pipe internal grinding machine

- Steel pipe external grinding machine

- Hydrostatic pipe testing machine

- steel pipe Flaring machine

- steel square pipe making machine

- steel pipe straightening machine

- steel pipe beveling machine

- Tee Making Machine

- Cold Drawning Machine

- Cold Elbow Machine

- Intermediate frequency power supply

- Graphite sprayer

- Seamless taper pipe machine

- seamless tapered steel pipe

- our customers

- news

- contact us

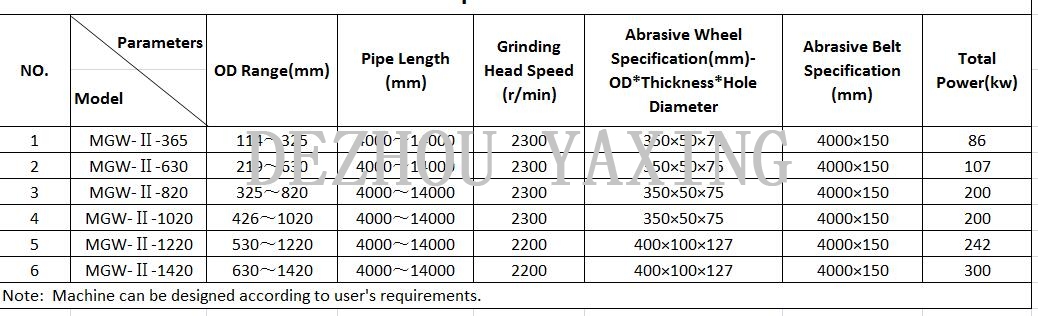

Steel Pipe External Grinding Machine

MGW-II Steel Pipe External Grinding Machine

1. Equipment uses:

This equipment is steel pipe external grinding and finishing equipment, which is mainly used to grind outside surface defects of various seamless steel pipe and straight welded pipe with stainless steel and alloy steel. And also it can grind and renovate

kinds of waste pipes outside surface. As to the strict requirement to the protection of environment, the equipment is very suitable for anticorrosion, grinding and antirust treatment for seamless steel pipe, straight welded pipe and spiral welded pipe.

Compared to other derusting technology, it is more safety and environmental.

2. Equipment technical parameters:

1) The equipment adopts 2-6 pcs of grinding heads. Steel pipe rotating spindle speed and pipe walking speed adopt frequency technology to adjust which can be suitable for grinding works with different kinds of material, pipe diameter and grinding amount.

2) Floatable grinding head abrasive wheel can float along with steel pipe bending degree which can guarantee the even of circular radial grinding amount on pipe surface. The equipment is the first choice especially the pipe surface needs large grinding amount.

3) Abrasive wheel specification:OD φ350~610mm ×IDφ75~127(220)mm×thickness 50~100mm , granularity 10#~36#

4) Abrasive belt specification:4000mm×150mm, granularity 24#-36#

5) Steel pipe turning roller bearing capacity: 10~50ton(design and manufacture according to user’s requirement)

6) Grinding head abrasive wheel grinding pressure of light model external grinding machine is controlled by bidirectional spring control. The lift of grinding head abrasive wheel is controlled by lift motor.

7) Air pressure adjustment of grinding head abrasive wheel grinding pressure of heavy model external grinding machine and lift of abrasive wheel are controlled by PLC programming control. It has realized smart control of whole production process and improved grinding quality and efficiency of steel pipe.

8) Monitor system is composed of video monitor system and spindle motor monitor system.

9) As user’s requirement to environment protection, it can be equipped with dust removal sound proof room with wet type centrifugal dedusting mechanism ( or dry type deduster ).

3. Equipment technical parameters:

1)diameter range:φ219~φ1420mm(sectional design and manufacturing the equipment);

2)pipe length:3~16m

4. Equipment structure:

underbed mechanism, grinding head mechanism, steel pipe turning operating mechanism, dust removal sound proof room, wet type dedusting mechanism ( or dry type deduster ), auto-feed water system, steel pipe turning plate loading and unloading mechanism (as required), pneumatic system, electric smart control system(PLC,HMI programming control system) and monitor system, operation desk(touch screen, monitor display screen).